Aluminum Chromate Conversion Process

Chromate conversion is the most common type of conversion coating that helps prevent corrosion on metals. The chromate conversion process provides corrosion resistance and conductivity without creating buildup. This process primer is cost-effective and used for bonding paint, lacquer, or rubber primarily on aluminum.

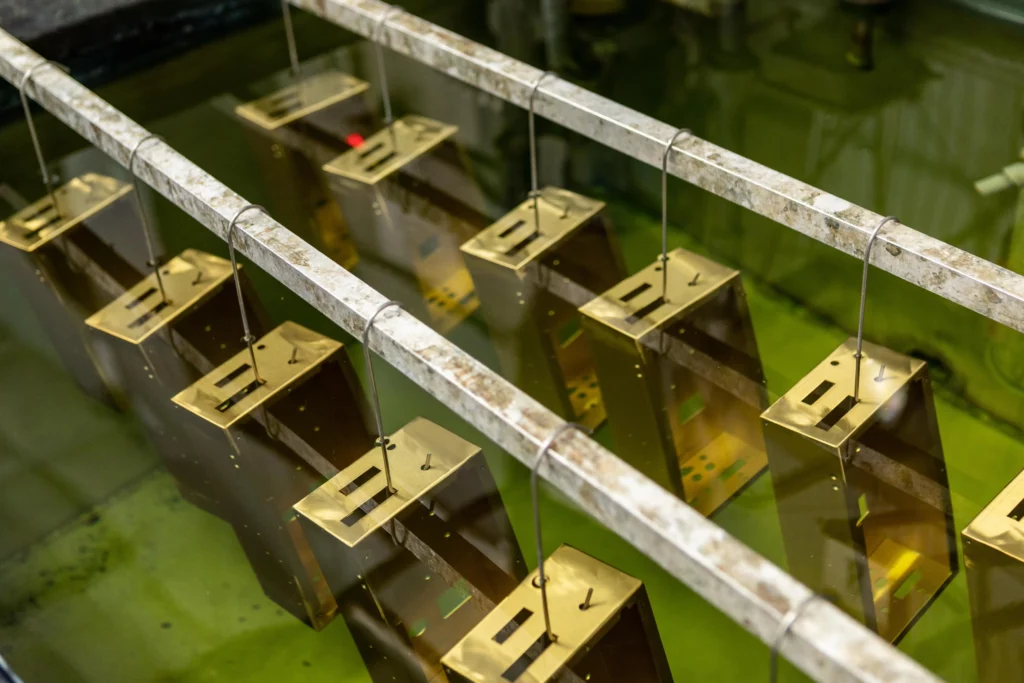

Here at Midwest Metal Products, we provide our own chromate conversion chem-film line to provide our customers with the most corrosion-resistant coating available.

- RoHS/REACH-compliant chem-film

- NADCAP Certified

- Eliminates powdery areas, breaks, and scratches

- Improves adhesion of finish primers and paints

The Process

Step 1: We begin our process by having the surface of the metal thoroughly cleaned and polished. It is essential to carry out this pretreatment to ensure that metals retain their anti-corrosive properties even when subjected to extreme temperatures or humidity. The chromate coatings can then self-heal these climate assaults and surface scratches.

Step 2: Next, we immerse the freshly cleaned metal surface in a water-based solution made up of chromium salts and acids. We also have the option to spray the metal with an acidic chromium coating.

Step 3: After we apply the chromate coat, we treat the metal with deionized water, run it through a rinsing bath, and then dry it. The colors of chromate coatings can be aesthetically pleasing and iridescent, as they range from bright yellows to dark brown/ greenish hues. The darker colors are usually thicker and provide better corrosion protection.

Aluminum Chromate Conversion

Type I and Type II

When it comes to chromate conversion, we offer Type I and Type II. Type I and Type II conversions are used to help provide protection against corrosion on unpainted surfaces/items.

Electrical

For electrical and electronic applications, we have a Class 3 coating that is highly effective due to its thinner coating. If you are looking for electrical conductivity, you will need to make sure that the chromate is the proper thickness.

Corrosion Inhibitor

Chromate is often applied to galvanized parts to make them stronger. It can be used for many different reasons, such as a corrosion inhibitor, primer, decorative finish, or to retain electrical conductivity.

Chromate Conversion is a very durable option to use on your materials. At Midwest Metal Products, we offer many options and will create a flawless finish. Have questions or need more information? Contact the Midwest Metal Products team today.