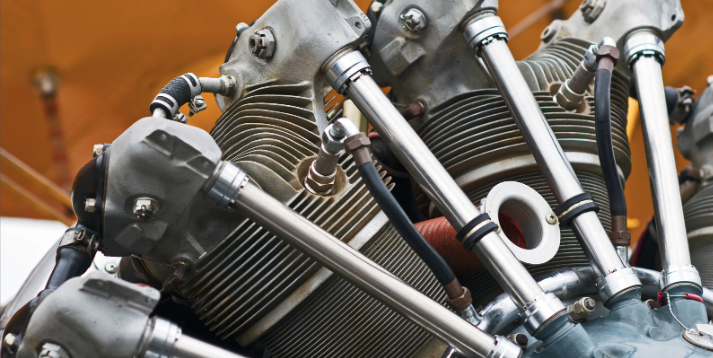

Custom. Cutting Edge. Conceptual

Aerospace Sheet Metal Fabrication Specialists

At Midwest Metal Products, we are a trusted aerospace supplier specializing in high-precision aerospace sheet metal fabrication. With decades of experience and a deep understanding of the aerospace industry’s stringent standards, we deliver custom components that meet the exacting demands of today’s leading aerospace manufacturers.

Aerospace Sheet Metal Expertise

Our aerospace sheet metal capabilities include:

Let’s Get to Work

Looking for an experienced aerospace sheet metal supplier who delivers accuracy, quality, and consistency? Contact Midwest Metal Products today to learn more about our aerospace manufacturing capabilities or request a quote for your next project.

Midwest Metal Products is a precision metal fabrication facility that has been serving the aerospace industry for over 55 years.