Custom. Cutting Edge. Conceptual

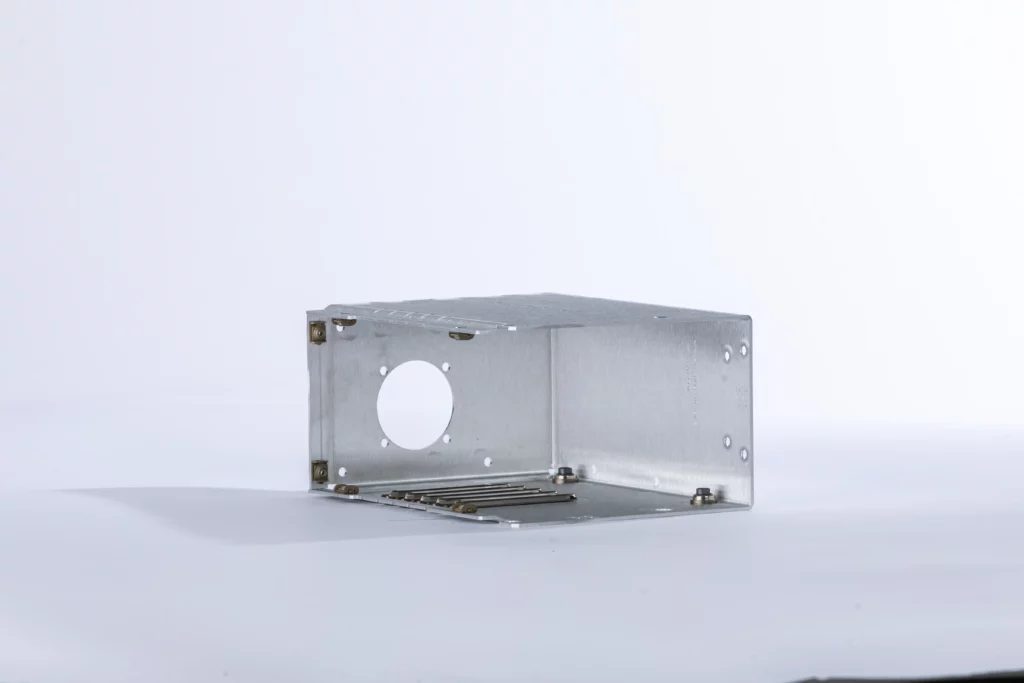

Metal Fabrication Specialists for Medical Equipment

Precision and accuracy are critical in the medical field. Midwest Metal Products has the experience and skill to manufacture the highest-quality medical equipment. For more than 55 years, we have manufactured custom medical equipment and devices for our customers across the world.

We adhere to the strictest industry standards and specifications to provide the medical equipment industry with the most effective and reliable equipment on the market. If you’re seeking the most advanced engineering of equipment and technology, MMP is your preferred vendor for medical equipment manufacturing.

We’re proud of the reputation we’ve built as a trusted provider in this industry. In all we do, we focus on quality, superior customer service, and on-time delivery.